H SERIES / HELICAL

ETS sells a variety of H Series or Helical spring energized seals, which are widely recognized for their effectiveness and reliability in static applications, particularly for rods and pistons in vacuum sealing systems. These specialized seals are crafted from a flat metal strip stock that is skillfully formed into a helix shape to ensure optimal performance. The standard material used for these seals is 17-7 PH stainless steel, though we also offer numerous other metals as additional options based on your specific needs. The innovative design of the spring generates a remarkably high load versus deflection curve, providing exceptional sealing capability. We would be pleased to serve as your trusted seal supplier!

Features

• Helical Wound Ribbon Spring with High Load vs Deflection

• Standard Inch Fractional and MIL-G-5514 Sizes

• Standard 17-7 ph Stainless Steel Springs

• NACE Compliant Springs Available

• Temperature Range from -360° F to 600° F.

• Vacuum to 3000 psi Standard / 10,000 Extended

• Available as External & Internal Pressure Face Seals

Recommended Applications

• Static Rod and Piston Seals

• Static Internal & External Pressure Face Seals

• Very Slow Dynamic Seals <10 sfpm

• Vacuum Sealing

• Applications below -100° F.

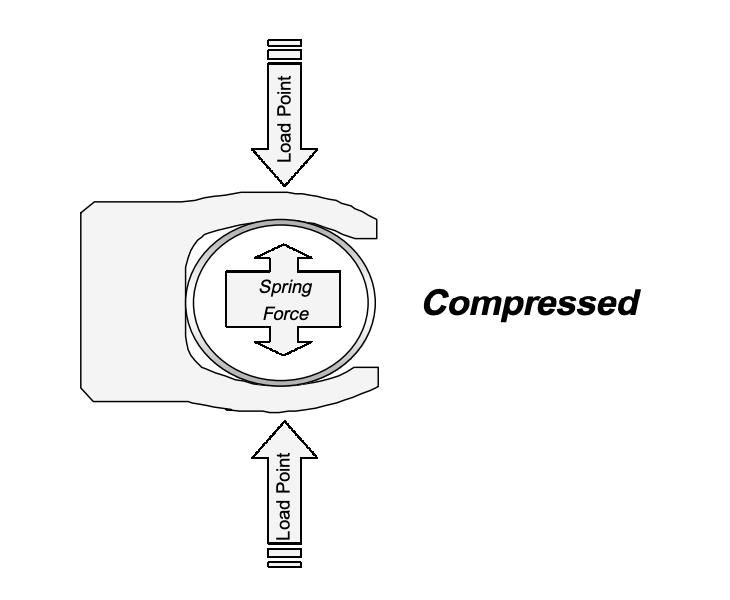

The helical spring design is intended for static applications due to the high unit load. It can be used in very slow or infrequent dynamic conditions when friction and wear are secondary concerns to positive sealing. The H Series spring produces evenly distributed load across each individual band, with very small gaps between the coils, This tight spacing provides near continuous load, reducing potential leak paths. This combined with the high unit load makes the H Series well suited for vacuum and cryogenic applications or when pressure is too low to energize the seal. The load provided by the H Series spring is directly through it’s center line. The lip design of the seal is a full radius at the sealing interface, providing maximum load to the contact points to effect a tight seal. The spring is welded at the ends and is retained in the seal by parallel side cuts in the spring cavity. When the seal is compressed into the hardware, the spring cavity is designed to allow the axial growth of the spring. The relatively small deflection range of the H Series spring prevents it from being used in applications having wide gland tolerances, eccentricity or misalignment. V or C Series seals should be considered for these conditions.